Graphite Grounding rods are an innovative grounding system that replaces traditional copper

grounding rods. Made from graphite and carbon fiber, they are environmentally friendly

highly durable, corrosion-resistant, and easy to install.

Can be used much longer than copper grounding rods.

Resistant to salt, acid, alkali, etc.

Easy to install and transport.

Superior grounding performance.

Made from recyclable materials, reducing environmental pollution.

In vast wind power farms,

Graphite Ground Rod play a crucial role

in establishing a stablegrounding system.

Reinforcing the grounding

system of transmission facilities

ensures safe transmission.

Establishing grounding systems

in buildings protects them

from lightning strikes.

Utilized as grounding systems in

various industries such as mining,

telecommunications, and railways.

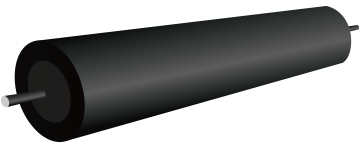

Size : 150mm x 1,000mm / weight : 22kg

Size : 200mm x 1,200mm / weight : 36kg

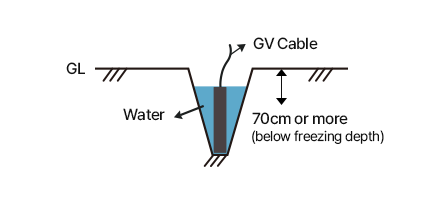

Excavate as shown in the figure below. (However, if installing under the basement floor, excavate only to the depth of the product height since it is below the frost line.)

Place the Graphite Ground Rod connected to the GV wire as shown in the figure below.

Pour water until the Graphite Ground Rod is submerged. (If there is groundwater in the excavated area, this step can be skipped.)

Backfill with the surrounding soil.

Connect using sleeve crimping or heat welding method (70SQ-95SQ).

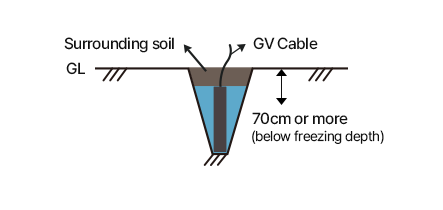

Excavate as shown in the figure below. (However, if installing under the basement floor, excavate only to the depth of the product height since it is below the frost line.)

Place the Graphite Ground Rod connected to the GV wire as shown in the figure below.

Pour water until the Graphite Ground Rod is submerged. (If there is groundwater in the excavated area, this step can be skipped.)

Backfill with the surrounding soil.

Connect using sleeve crimping or heat welding method (70SQ-95SQ).