Miracle Earth is a conductive grounding resistance reduction material

that increases the contact area between the grounding electrode and the ground,

providing excellent performance. In addition to reducing ground resistance, it instantly

dissipates abnormal currents to the ground in the event of lightning or abnormal voltage.

| Appearance | Light gray fine powder |

|---|---|

| Packing unit | 10kg/bag, 20kg/bag |

| Electrical resistivity (Ω · m) | Below 0.1 |

|

Capacity per unit volume about(kg/m3) |

About1,260(kg/m3) |

|

Compressive strength (kgf/cm2)-7days |

Over 200(kgf/cm2) |

| Flexural strength(kgf/cm2) | Over 20(kgf/cm2) |

| Product name | Application | Capacity(NET.) kg/bag |

|---|---|---|

| Miracle Earth | ommunication use | 10, 20 |

| general use | 10, 20 |

For requiring ground resistance of 10Ω or more like lightning rod.

For good ground conditions.

For requiring ground resistance of 5Ω or less. For requiring lower ground resistance.

For weathered soil, sandy soil, rock bed.

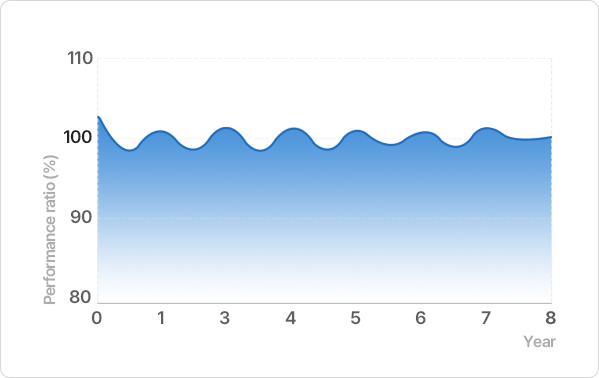

It has good compatibility with the soil and also has an

excellent ground effect by expanding the ground area.

It makes easily construction and enables you to

construct freely depending on field conditions.

By using ground resistance reduction agents,

construction and material costs are saved,

corrosion is prevented for a semi-permanent effect,

and maintenance is not required.

A variety of construction can be made depending

on ground conditions such as buried ground wire,

mesh, ground rod. and boring.

Prepare M-EARTH products, mixing containers, and water (4~6L) to be used.

Mix 4 to 6L of water per 10 kg of M-EARTH in a container and mix as evenly as possible.

Apply the mixed M-EARTH so that the ground electrode (ground line) is sufficiently wrapped.

The grounding effect is proportional to the grounding area, making the grounding area as thick and wide as possible

The earth's inherent resistance (Ω·m) varies depending on the depth, density, and moisture content of the soil. Before grounding, analyze the earth's inherent resistance or soil to select the optimal depth. Then, use a crawadill or similar equipment to bore (about 5-20 meters deep), connect the ground copper rod to the spiral wire, insert it, and put the mixed M-EARTH into the space.

For grounding construction using a bare copper wire (50mm² or more) method, a pit with a width of 50cm and a depth of 75cm or more is created as shown in the figure. The bare copper wire is positioned in the center of the pit, then M-EARTH is applied at a thickness of 5cm to sufficiently cover the bare copper wire, and the pit is backfilled with soil.

Ground rod electrodes (L:1.0m to 3.0m) are most often used for various ground works. Ground rod electrodes are easy to construct, and in particular, parallel connection type ground rod electrodes are constructed in connection until the desired ground resistance is obtained. After plating a pit (diameter 30-50 cm) as shown in the figure, a ground copper rod is type, and a mixed M-EARTH is applied.

A large ground electrode is formed by connecting a plurality of buried ground wires to each other in a lattice shape. In particular, it is used in power plants, substations, telephone stations, intelligent buildings, and hospitals that require low ground resistance. In addition, mash, ground rods, and copper plates are used.